Time for an update as I managed to get some time to move things on:

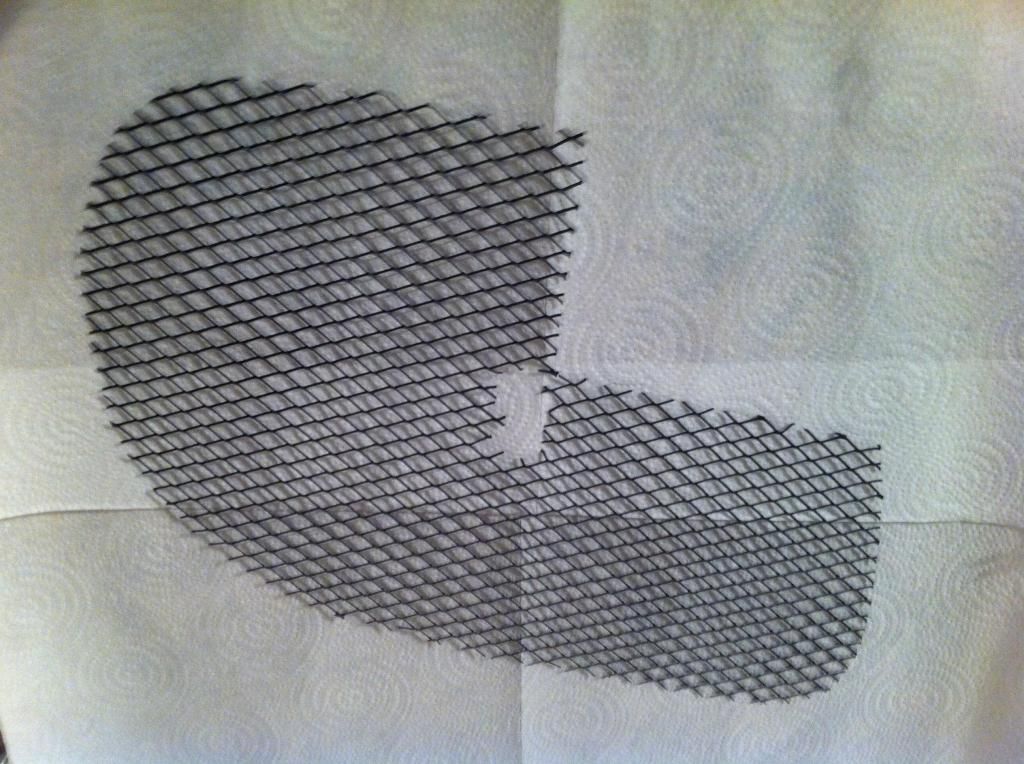

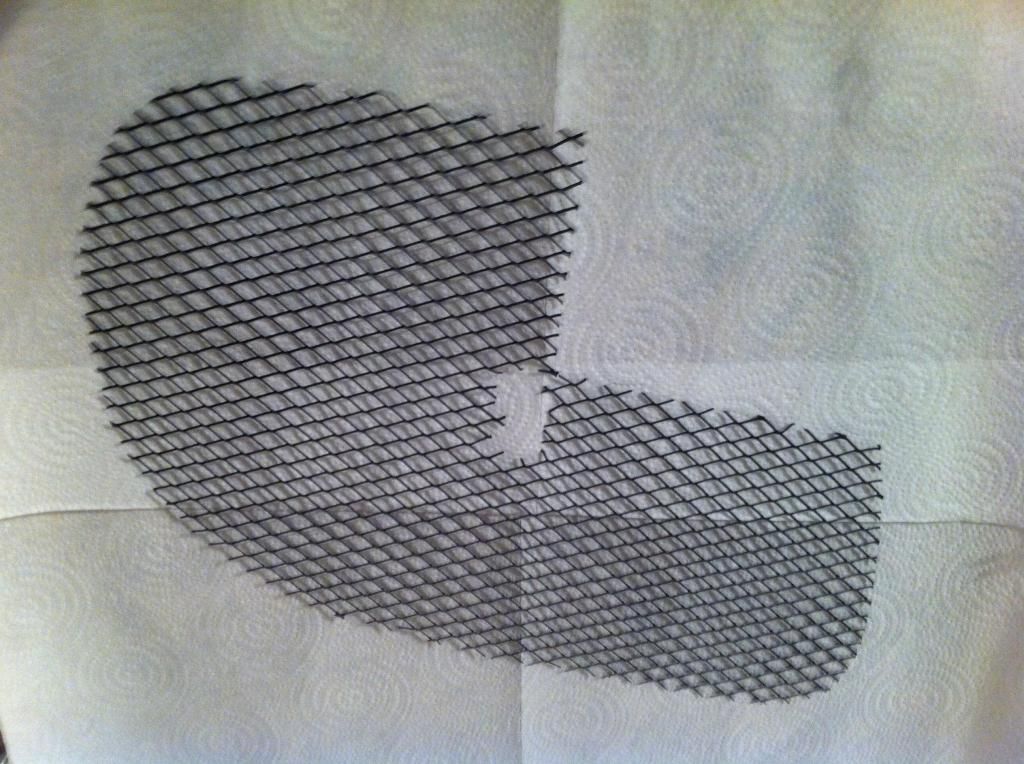

Mesh grills cut to size from a card template, painted and fitted with small black tie straps to rear of front grills. These are easily removable if need be

Crankshaft front pulley seal had a slight leak so pulley removed and area cleaned up with brake cleaner. The seal was removed by drilling a small hole in its face and using a self tapping screw and puller.

My cam timing kit finally arrived so tappet housings, tappets, cams etc were cleaned and refitted using the workshop manual (thanks Infrasilver!). Rather than chance it I also replaced the inlet cam sprocket stretch bolts and all the seals in here (not all are included in the head rebuild kit). This whole process looks quite involved but is not too bad provided you stick to the manual, work methodically and double check as you go.

Cam covers were chemically cleaned with the cylinder heads and re-fitted with the Porsche approved sealant

The timing procedure involves locking the front pulley at a known point using the tool supplied in the timing kit (a bolt would also work) and then fitting the inlet and exhaust cams and locking the position using their end slots and the holding tool. The cam sprocket bolts are left loose and the front pulley locking pin removed and the crank is rotated in a clockwise direction until TDC is reached. At this point the cam sprocket bolts can be tightened and the timing is then set.

The crank then needs rotating 360 deg (or thereabouts) and the other cylinder bank can be done.

I found after doing this that both my exhaust cams were very slightly off when trying to refit the cam end plate tool (possibly as a result of initial chain slack) so I made some more adjustments to ensure it was exactly as it should be.

Low temp thermostat and new water pump fitted

More next time

:thumb: