ELA

Barcelona

- Joined

- 30 Aug 2011

- Messages

- 1,424

Another little update now that the fuel system is complete.

Made another little titanium mounting bracket for the rigid section of the fuel return pipe:

Which fits here:

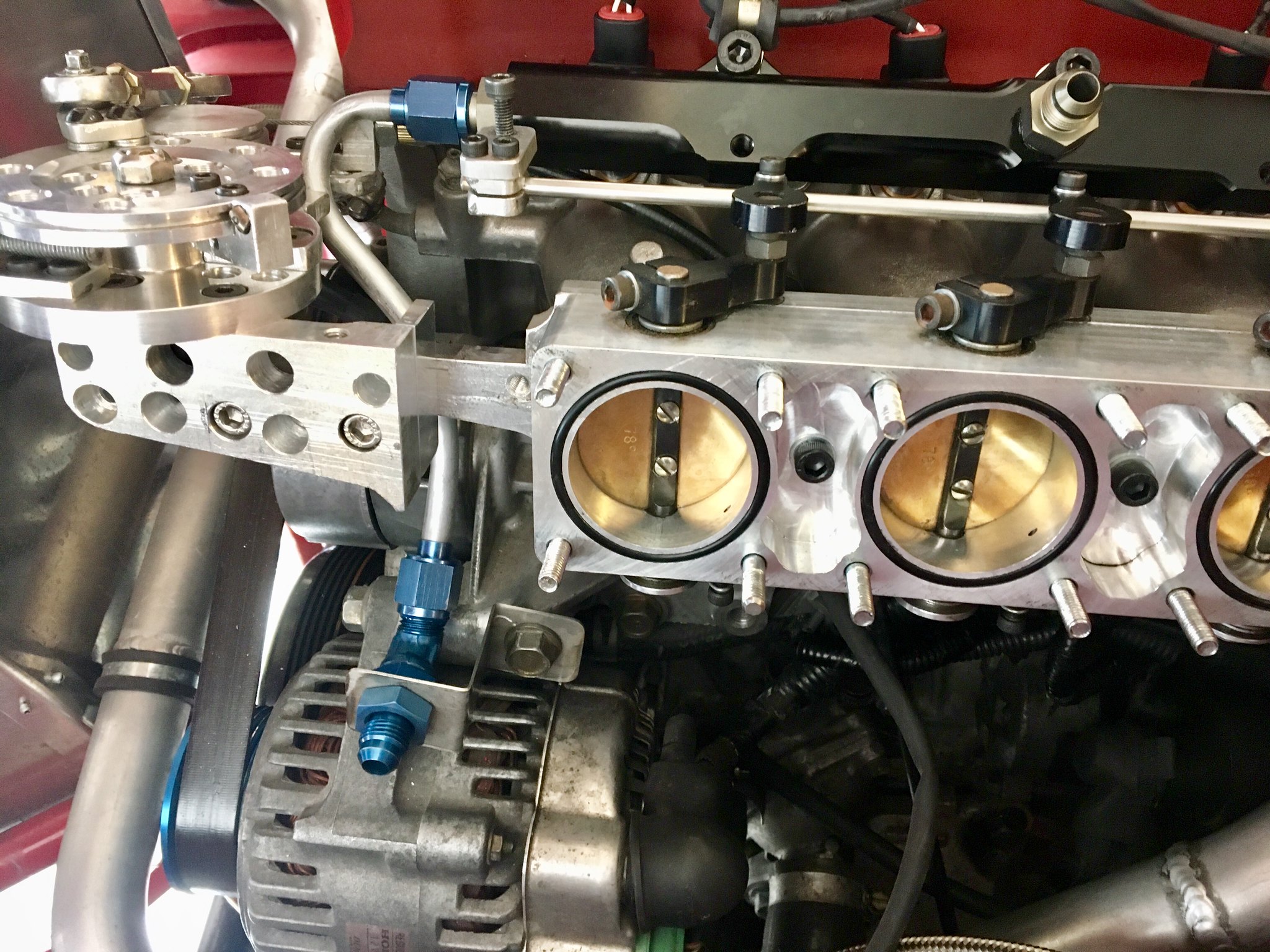

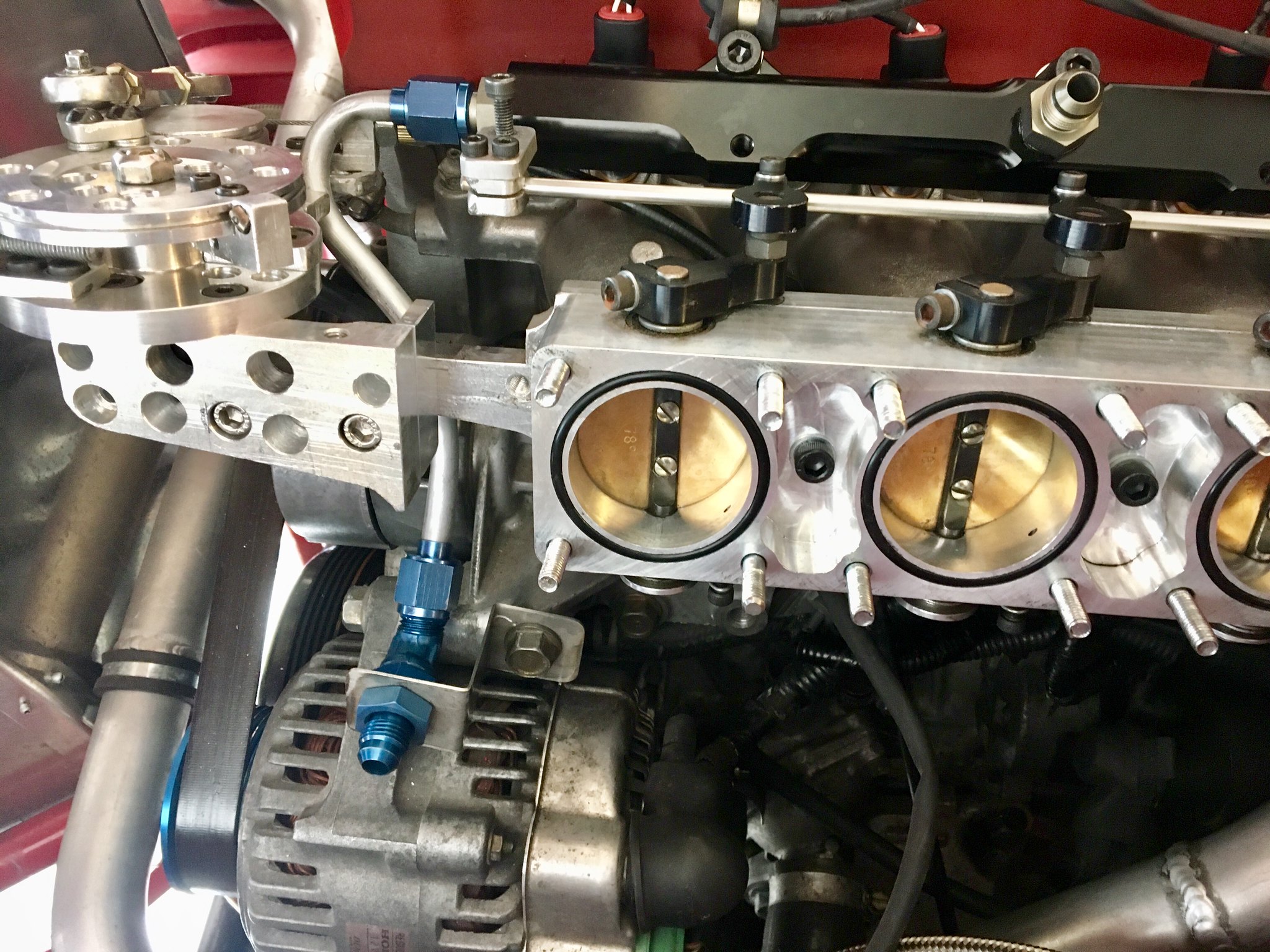

Engine bay fuel lines new layout:

This picture gives a close up high-lighting the tight tolerance clearance issues referred to earlier:

Final assembly:

Made another little titanium mounting bracket for the rigid section of the fuel return pipe:

Which fits here:

Engine bay fuel lines new layout:

This picture gives a close up high-lighting the tight tolerance clearance issues referred to earlier:

Final assembly: