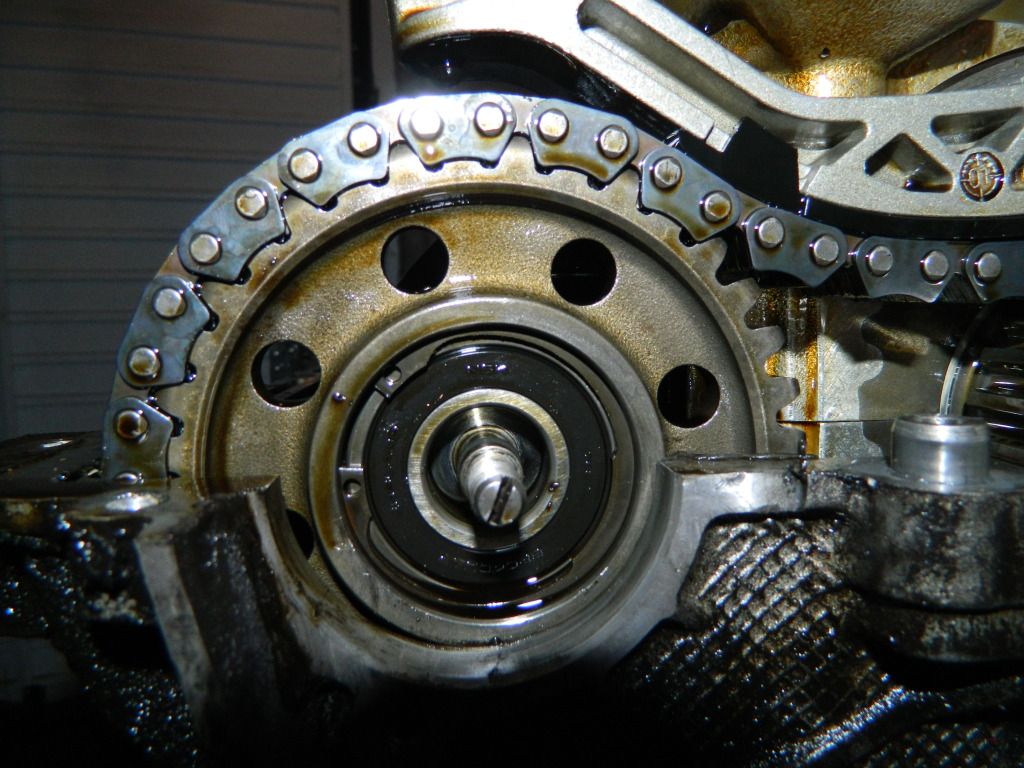

I've seen several threads where it is claimed that an oil leak from the IMS area is indicative of an IMS bearing failure.

Not even taking in to account the possibility of an RMS issue, surely an actual leak from the IMS bearing cover has more to do with it's O ring?

In addition to this it is advised to run a replacement bearing without it's own seals so again this suggests that the cover should be oil tight?

Not even taking in to account the possibility of an RMS issue, surely an actual leak from the IMS bearing cover has more to do with it's O ring?

In addition to this it is advised to run a replacement bearing without it's own seals so again this suggests that the cover should be oil tight?