systemmeister

Spa-Francorchamps

- Joined

- 25 Jun 2014

- Messages

- 324

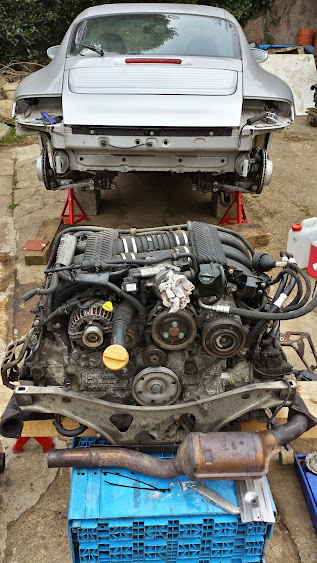

Have had the 996 about a year now and have treated her to some remedial bodywork, full new genuine shocks, springs, roll bars and top mounts all round.

She's been treated gently since, with scarce few miles extra under her belt.

I've promised to get the mechanical engine and transmission work done over winter but waited for the right time.

Anyway, the time is here to get cracking.

Bought her some new silencers courtesy of Milltek in shiny stainless - but this will be the icing on the cake.

The work planned;

* Clutch

* Vario Cam solenoid (one or both)

* Rear main seal (engine)

* IMS bearing

* Air/oil separator

* Cam cover seals

* Spark tubes and O-rings

* Oil change - lots of lovely Mobil 1.

I'm doing the donkey work myself, with assistance for the tricky bits by a very skilled engineer who works on these all day every day

Photos tell the story so far......

Engine removal at the weekend.......

She's been treated gently since, with scarce few miles extra under her belt.

I've promised to get the mechanical engine and transmission work done over winter but waited for the right time.

Anyway, the time is here to get cracking.

Bought her some new silencers courtesy of Milltek in shiny stainless - but this will be the icing on the cake.

The work planned;

* Clutch

* Vario Cam solenoid (one or both)

* Rear main seal (engine)

* IMS bearing

* Air/oil separator

* Cam cover seals

* Spark tubes and O-rings

* Oil change - lots of lovely Mobil 1.

I'm doing the donkey work myself, with assistance for the tricky bits by a very skilled engineer who works on these all day every day

Photos tell the story so far......

Engine removal at the weekend.......