infrasilver

Moderator

- Joined

- 4 Oct 2010

- Messages

- 9,934

:thumbs:

More to follow with Goodwood.

More to follow with Goodwood.

Welcome to the @Porsche911UK website. Register a free account today to become a member! Sign up is quick and easy, then you can view, participate in topics and posts across the site that covers all things Porsche.

Already registered and looking to recovery your account, select 'login in' and then the 'forget your password' option.

alex yates said::worship:

Can you not bore it out to 3.4? :lol:

wasz said:Love it.

I always regret passing up a nice 944 s2 and a 968 sport that I passed up in 2009.

The 3.0 is a peach, the largest power output per litre engine of its day?

I use Halfords brushable grey primer and it looks perfect with no brush marks.wasz said:What did you paint the bells with? Got to do my new discs, I just have some primer and silver wheel paint

Porsche 991: 2011-2019

Porsche 991: 2011-2019

Porsche 997: 2004-2012

Porsche 997: 2004-2012

Porsche 996: 1997-2005

Porsche 996: 1997-2005

Porsche 993: 1993-1998

Porsche 993: 1993-1998

Porsche 964: 1989-1993

Porsche 964: 1989-1993

Porsche Carrera 3.2: 1983-1989

Porsche Carrera 3.2: 1983-1989

Porsche Carrera SC: 1977-1983

Porsche Carrera SC: 1977-1983

Porsche 930 Turbo: 1975-1989

Porsche 930 Turbo: 1975-1989

Porsche Early 911: 1964-1977

Porsche Early 911: 1964-1977

Porsche Carrera GT

Porsche Carrera GT

Porsche GT1

Porsche GT1

Porsche 959

Porsche 959

Porsche Macan : 2013-

Porsche Macan : 2013-

Porsche Panamera : 2009-

Porsche Panamera : 2009-

Porsche Cayman: 2005-

Porsche Cayman: 2005-

Porsche Cayenne: 2003-

Porsche Cayenne: 2003-

Porsche Boxster: 1997-

Porsche Boxster: 1997-

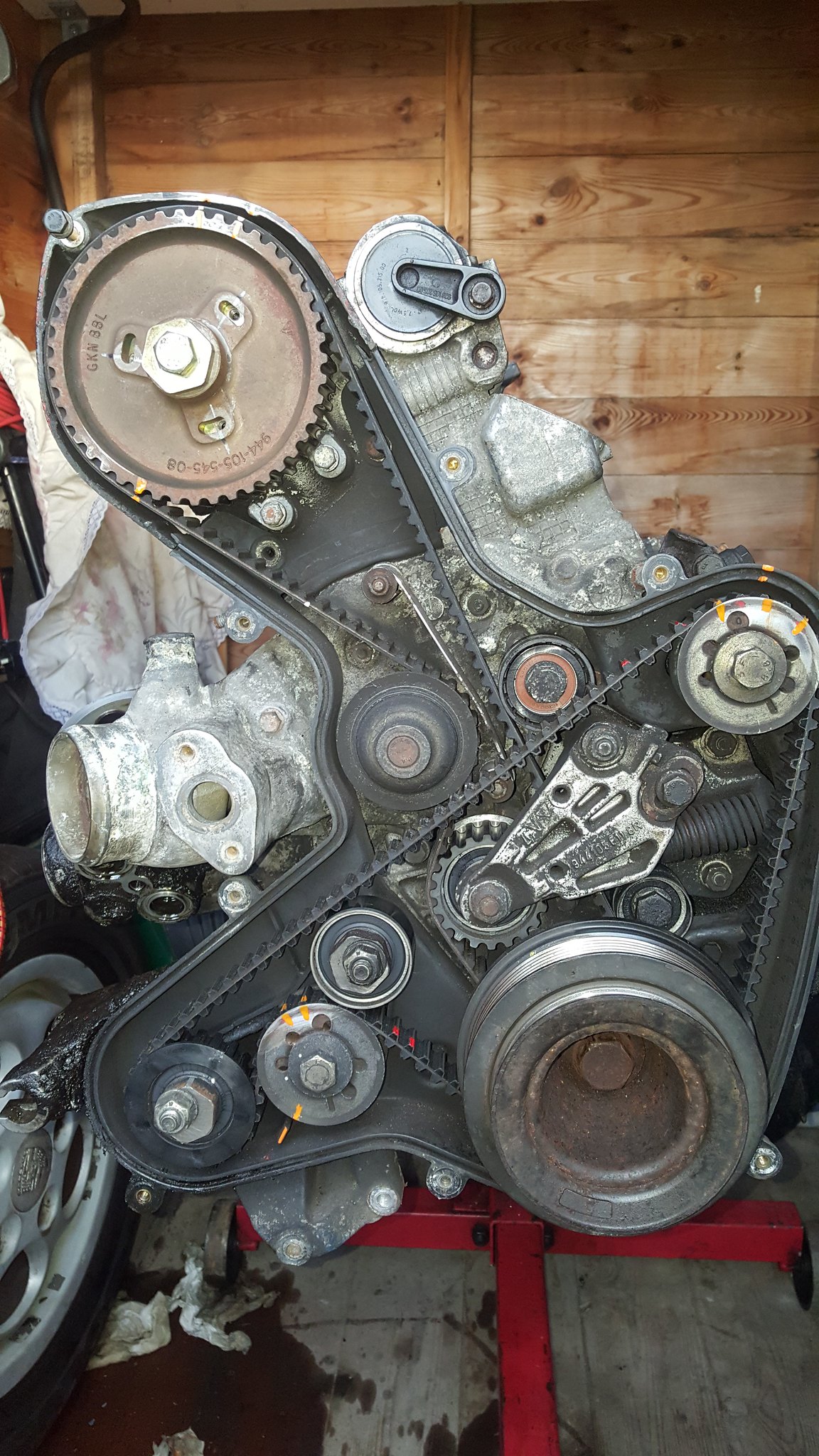

Porsche 968

Porsche 968

Porsche 944

Porsche 944

Porsche 924

Porsche 924

Porsche 914

Porsche 914

Porsche 912

Porsche 912

Porsche 904

Porsche 904

Porsche 550

Porsche 550

Porsche 356 Speedster

Porsche 356 Speedster

Porsche 356

Porsche 356